Groov EPIC Edge Programmable Industrial Controller

Groove EPIC represents the new generation of the industrial control system from OPTO 22. It is a unique system that combines the features of a modular controller, display panel and communication device with the ability of secure connection to the IIoT (Industrial Internet of Things) network. Groove EPIC has a powerful quad core processor, two independent Ethernet interfaces and two USB serial communication ports. The device incorporates also a high resolution touch screen, which can be used as a display panel or perform a function of system configuration and diagnostics. An additional HDMI output also allows direct connection to an optional external display. OPTO 22 offers also complete new set of high density (up to 24 points) I/O modules with the possibility of hot swapping during operation. The robust design of the control system allows operation in harsh environments in the temperature range between -20 and 70 ° C.

SNAP- PAC S

SNAP PAC s is a standalone industrial control processor unit. With its high processing power, communication capabilities and large memory, controller can manage the most demanding processes. It can communicate with all OPTO22 Ethernet input/output units (PAC EB1, PAC EB2) and programmable input/output processors (PAC R1, PAC R2) in the network.

Controller has two separated Ethernet interfaces, which allows physical separation of process control network from supervision/information network. Two PAC S2 controllers can be configured as redundant control system. Controller also provides serial RS 232/RS485 communication ports where old OPTO 22 G4 serial I/O units can be connected.

Controller accommodates 32 MB of RAm, 16 MB of Flash EEPROM and 8 MB of battery-backed RAM. Its powerful CPU can run up to 32 flowcharts simultaneously.

SNAP- PAC R

SNAP PAC R programmable input/output processor combines the features of an I/O unit and a controller processor in one device. It comes with a powerful processor, 16 MB of RAM, 8 MB of Flash EEPROM memory and 2 MB of battery-backed RAM. With these features, it is also suitable to control complex processes.

PAC R can also exchange data with other Ethernet I/O units and standalone PAC S processors on the network. Its two independent Ethernet interface also allow redundant configuration of control systems. In addition to all standard SNAP I/O modules, PAC R allows connection of up to eight serial communication modules on the backplane. This is a unique solution, which simplifies implementation of non-standard protocols. PAC R is also available with an additional WLAN interface.

SNAP PAC EB

SNAP Input-output modules

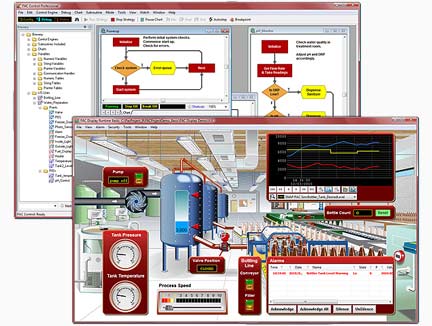

PAC Project™ programming tool

Opto 22 // mag. Jaroslav Toličič // jaroslav.tolicic@metronik.si // +3861/514-08-16

Opto 22 // mag. Jaroslav Toličič // jaroslav.tolicic@metronik.si // +3861/514-08-16